Screws are widely used as fasteners for fastening connections. Widely used industries, including energy, electronics, electrical appliances, machinery, and so on, there are standard parts and non-standard parts, screw fastener surface treatment is a process of forming a covering layer on the surface of the workpiece by a certain method, the purpose is to give the product surface beautiful, anti-corrosion effect.

1. The screw to be blacked is placed in the solution tank (145±5℃) of sodium hydroxide and sodium nitrite oxidant to heat and oxidize, so that the surface of the metal screw generates a layer of magnetic ferric oxide film, the thickness is generally 0.6 -- 0.8μm black or blue black.

(2) Phosphating is a chemical and electrochemical reaction to form a phosphate chemical conversion film process, the phosphate conversion film formed is called phosphating film. The purpose of phosphating is mainly to provide protection for the base metal and prevent the metal from being corroded to a certain extent.

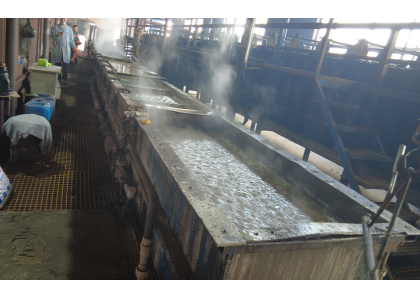

3. Hot dipping zinc is to immerse the screw after rust removal into the zinc liquid melted at a high temperature of 600 ° C, so that the surface of the steel member is attached to the zinc layer, the thickness of the zinc layer shall not be less than 65μm for the thin plate below 5mm, and the thick plate above 5mm shall not be less than 86μm. So as to play the purpose of corrosion prevention.

4. DACROMET is the translation and abbreviation of Dacromet, referred to as Dacromet, named zinc chromium coating, is a new type of anti-corrosion coating with zinc powder, aluminum powder, chromic acid and deionized water as the main components. Suitable for high strength fasteners with high anti-corrosion requirements.

5. Electrogalvanizing: also known as cold galvanizing, is the process of forming a uniform, dense and well-combined metal or alloy deposition layer on the surface of the parts by electrolysis. Electrogalvanizing is a commonly used coating for fasteners. It is cheaper and looks better. It can be black or army green. However, its corrosion resistance is general, the general electrogalvanizing neutral salt spray test within 72 hours, there are also special sealers, making the neutral salt spray test of more than 200 hours, but the price is expensive, 5 to 8 times that of general galvanizing.