It usually includes the following 13 categories of parts:

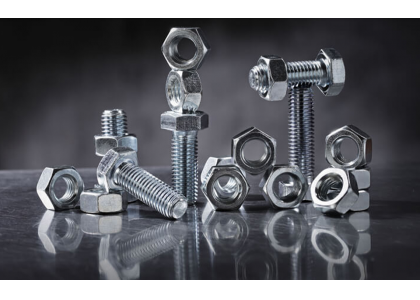

1. Bolt: A type of fastener composed of a head and a screw (a cylinder with external threads), which needs to be matched with the nut for fastening and connecting two parts with a through hole. This type of connection is called bolted connection. If the nut is unscrewed from the bolt, the two parts can be separated, so the bolt connection is a detachable connection.

2. Stud: no head, only a class of fasteners with external threads at both ends. When connected, one end of it must be screwed into the part with an internal threaded hole, the other end through the part with a through hole, and then screw on the nut, even if the two parts are tightly connected into a single piece. This connection form is called a stud connection, which is also a detachable connection. It is mainly used for occasions where one of the connected parts is thick, requires compact structure, or is not suitable for bolted connection due to frequent disassembly.

3. Screw: It is also a kind of fastener composed of two parts of the head and screw, which can be divided into three categories according to the use: machine screws, setting screws and special purpose screws. Machine screws are mainly used for the fastening connection between a part with a tight threaded hole and a part with a through hole, without the need for nuts (this connection form is called screw connection, and it is also a removable connection; It can also be used in conjunction with nuts for fastening connections between two parts with through holes.) The setting screw is mainly used to fix the relative position between two parts. Special purpose screws such as ring screws for lifting parts.

4. Nut: with internal thread holes, the shape is generally shown as a flat hexagonal column, there are also flat square column or flat cylinder, with bolts, studs or machine screws, used to fasten the connection of two parts, so that it becomes a whole.

5. Self-tapping screws: similar to machine screws, but the thread on the screw is a special self-tapping screw thread. Used to fasten the connection of two thin metal components, so that it becomes a whole, the member needs to make a small hole in advance, because the screw has a high hardness, can be directly screwed into the hole of the member, so that the member forms a response to the internal thread

6. Wood screw: it is also similar to machine screws, but the thread on the screw is a special wood screw thread, which can be directly screwed into the wooden component (or parts) for fastening a metal (or non-metal) part with a through hole with a wooden component. This connection is also a detachable connection.

7. Washer: A type of fastener with an oblate ring shape. Placed between the supporting surface of the bolt, screw or nut and the surface of the connected part, it has the function of increasing the contact surface area of the connected part, reducing the pressure per unit area and protecting the surface of the connected part from being damaged; Another type of elastic washer can also play a role in preventing the nut from loosening.

8. Stop ring: It is installed in the shaft slot or hole slot of the machine and equipment, and plays the role of preventing the parts on the shaft or hole from moving left and right.

9. Pin: mainly for parts positioning, and some can also be used for parts connection, fixing parts, transmitting power or locking other fasteners.

10. Rivets: A type of fastener composed of two parts of the head and the nail rod, used to fasten and connect two parts (or components) with a pass hole to make it a whole. This connection form is called rivet connection, referred to as riveting. Genus and non-detachable connection. Because in order to separate the two parts connected together, the rivets on the parts must be destroyed.

11. Assemblies and connecting pairs: Assemblies refer to a class of fasteners that are supplied in combination, such as machine screws (or bolts, self-supplied screws) and flat washers (or spring washers, locking washers); Connection pair refers to a type of fastener supplied by a combination of certain special bolts, nuts and washers

12. Welding nails: due to the heterogeneous fasteners composed of light energy and nail head (or no nail head), the welding method is used to fix him to a part (or component) above, so as to connect with other parts.

13. Wire screw sleeve: Wire screw sleeve is a new type of threaded connection element, is made of high strength, high precision corrosion resistance diamond wire refining. Shaped like a spring, it is installed in a specific screw hole of the matrix, and its inner surface forms a standard thread. When matched with screws (bolts), it can significantly improve the strength and wear resistance of the thread connection; Especially in aluminum, magnesium, cast iron, plastic and other low strength materials. The locking type is to add a ring or several rings of locking rings on the basis of the ordinary type. Xinxiang Yongda Industrial Co., Ltd. is specialized in the production of steel wire screw sleeve manufacturers, it is recommended that the steel wire screw sleeve embedded in the thread of aluminum, magnesium alloy, cast iron, glass steel, plastic and other low-strength engineering materials, can form standard M, MJ threads, with continuous strength, impact resistance and wear resistance functions, and can disperse stress to protect the matrix thread, greatly extending the service life of the matrix. At the same time, the force of the thread is improved, the elastic connection is formed, and the pitch and half Angle error of the tooth type between the internal and external threads are eliminated, so that the load on the thread is evenly distributed, and the matrix thread is protected from damage and the service life is extended