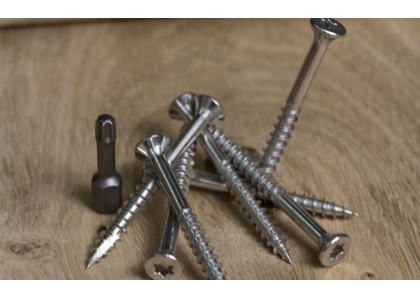

Stainless steel screws are widely used in various types of products in the fasteners, its solid connection to the product material for the use of safety and reliability is essential. However, sometimes the stainless steel screws may be loose, affecting the stability of the connection. In addition, stainless steel screws may be slightly magnetic, which may cause interference in some applications.

First, the problem of stainless steel screws

The use of resilient materials: specific resilient materials (such as engineering resin materials) are coated on the threads of stainless steel screws to create friction with nuts or product materials, forming vibration and absolute resistance, effectively preventing screw loosening.

Glue: The thread of the stainless steel screw is coated with anti-fall glue (a kind of glue with high adhesion and non-toxicity), which forms super adhesion after drying, so that the stainless steel screw and the nut or the product screw hole are closely combined to achieve the anti-loosening effect.

Second, the demagnetization method of stainless steel screws

High temperature solution treatment: Through the high temperature solution treatment of stainless steel screws, the austenitic structure changes, thereby eliminating the magnetic properties of the screws. However, solution treatment may have an impact on the mechanical properties of the screws and needs to be carefully considered.

Conclusion: In order to ensure that the stainless steel screws are firmly connected to the product and prevent loosening problems, the method of elastic material or dispensing can be taken. For the magnetic problems of stainless steel screws, they can be degaussed by high temperature solution treatment. In practical applications, suitable anti-loosening and degaussing methods are selected according to the specific requirements and environment to provide a solid connection and good performance.