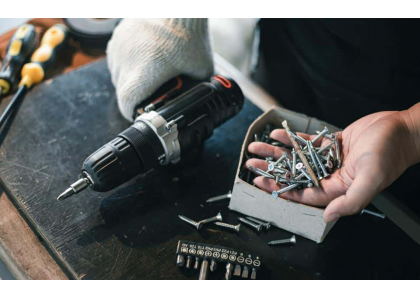

The screw is a screw assembled in the threaded hole, that is, a part with an internal threaded hole, and a connection between the parts with a through hole, do not need to be matched with the nut, this connection is removable connection; Machine screws can also be used with nuts for fastening connections between two parts with through holes. When installing machine screws, it is necessary to drill and tap teeth first, and assemble with relatively small torque.

Self-tapping screw is also called fast tooth screw, when using the first drilling, but do not tap, because its tooth thread is self-tapping type, can be directly screwed into the workpiece, to use a larger torque assembly.

From the appearance point of view, the diameter of the machine screw is uniform from beginning to end, the tail of the tapping screw is pointed, and the more the end is finer; The head of the organic screw is flat, the front of the tooth is the same as the bottom of the tooth, the tooth Angle is 60°, the thread of the tapping screw is wider, and the tooth Angle is generally less than 60°.

In addition to the difference in appearance and assembly, the use of machine screws and self-tapping screws is also different. Machine screws are used more in machine equipment or hard materials, such as connecting various components in the field of mechanical manufacturing, connecting engine cylinder heads in automobile production, manufacturing and assembly of various furniture, and steel structure buildings in construction; Self-tapping screws are mostly used in non-metal or soft metal materials such as wood, steel plate, aluminum, such as various parts of fixed furniture, fixed mechanical parts, motors, gears, bearings, etc.